Design Guidelines for SLS 3D Printing

Designing for Selective Laser Sintering (SLS) requires careful attention to wall thickness, tolerances, shrinkage, and part orientation. Unlike SLA or FDM, SLS allows complex geometries without support structures, but following design guidelines is essential for accuracy and repeatability. In this guide, we cover key rules for successful SLS design, from minimum feature sizes to assembly fits, as well as how industries like aerospace, automotive, and medical rely on precision in SLS printing.

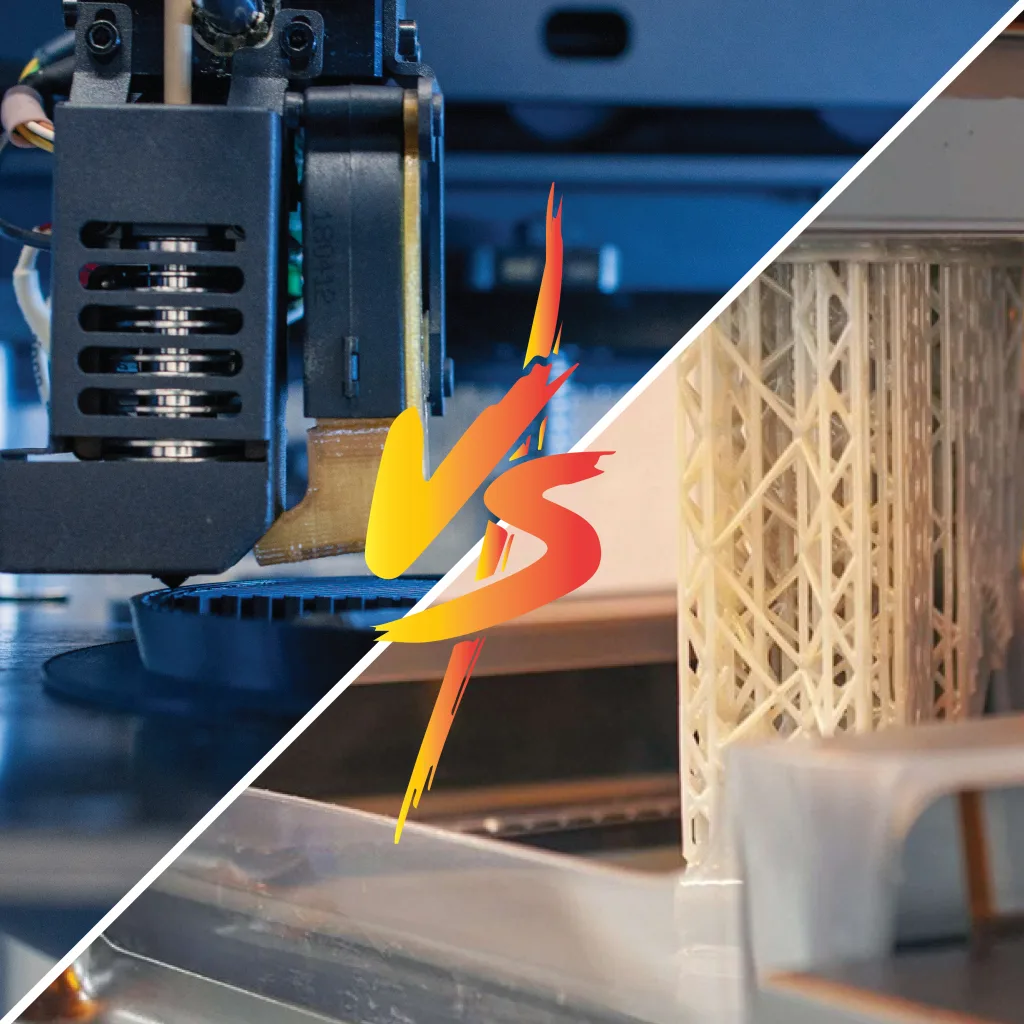

SLA vs FDM: Which 3D Printing Process Is Best for Your Prototype?

Compare SLA vs FDM 3D printing for prototypes. Discover key differences in strength, accuracy, surface finish, cost and when to use each process in product development.

A Guide to SLA Resin Materials for Industrial 3D Printing

Explore the properties, applications and selection criteria of SLA resin materials for industrial 3D printing, including engineering, medical, flexible and high-temperature options.

PLA, ABS or PETG? Choosing the Right Material for FDM 3D Printing Projects

Choosing between PLA, ABS, and PETG is critical for reliable and functional FDM 3D prints. This guide outlines key differences in performance, durability, and printability to help engineers, designers, and procurement teams make informed decisions.

Designing for FDM: How to Optimise Your 3D Print for Strength and Accuracy

Learn how to design FDM 3D printed parts for maximum strength, accuracy, and function. Covers wall thickness, infill, orientation, tolerances, and materials.

Beginner’s Guide to FDM vs SLA: Which 3D Printing Method Is Best?

Compare SLA 3D printers and FDM printing methods for cost, accuracy, and detail. A clear guide for beginners choosing their first 3D printer.