Vapour Smoothing vs Traditional Finishing: Which is Better for Nylon Parts?

Discover the key differences between vapour smoothing and traditional finishing for Nylon 3D printed parts. Learn how vapour smoothing enhances surface quality, seals pores, and improves durability compared to sanding, painting, and bead blasting.

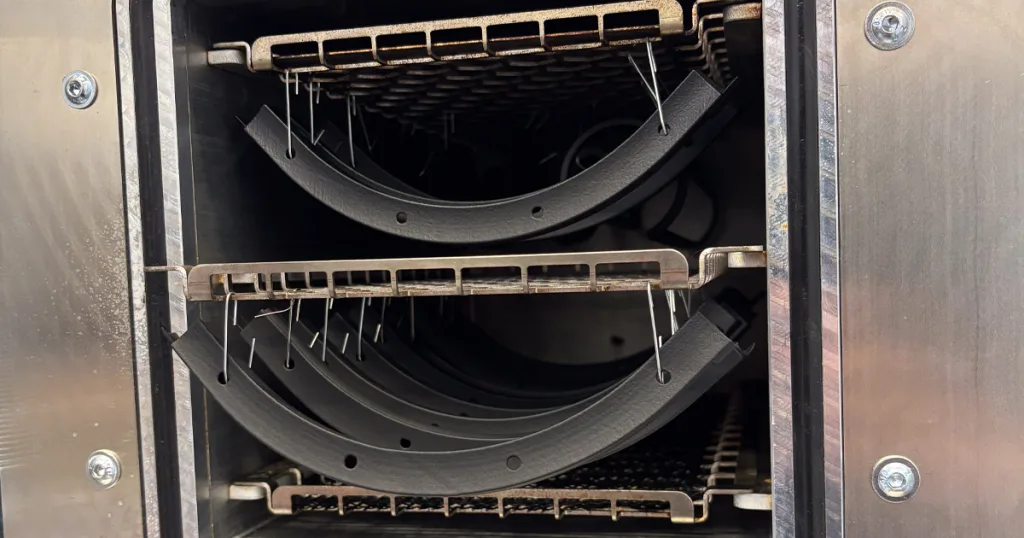

Product Review: AMT PostPro SFX Vapour Smoothing Machine

Our review of the AMT PostPro SFX Vapour Smoothing Machine shows how this system delivers consistent, injection-moulded finishes on 3D printed parts — improving surface quality and production efficiency.

Case Study: ARX Security

SGD 3D partnered with ARX Security to produce detailed scale models of their modular barrier systems using SLS 3D printing in Nylon PA12 GF. The lightweight, durable models were vapour smoothed and colour-matched for global trade shows, helping ARX showcase their products with precision and impact.

3D Printing in Engineering Education – Sheffield’s STEM Revolution

Education 3D printing in Sheffield is transforming how students learn engineering. By combining CAD design, 3D scanning, and hands-on manufacturing, schools and universities are preparing the next generation of skilled STEM professionals through practical, industry-ready experience.

Top 5 Design Mistakes to Avoid in SLS 3D Printing

Avoid the most common design errors in SLS 3D printing. Learn how to improve wall thickness, prevent warping, and optimise your Nylon PA12 and PA12 GF parts for stronger, more reliable results.

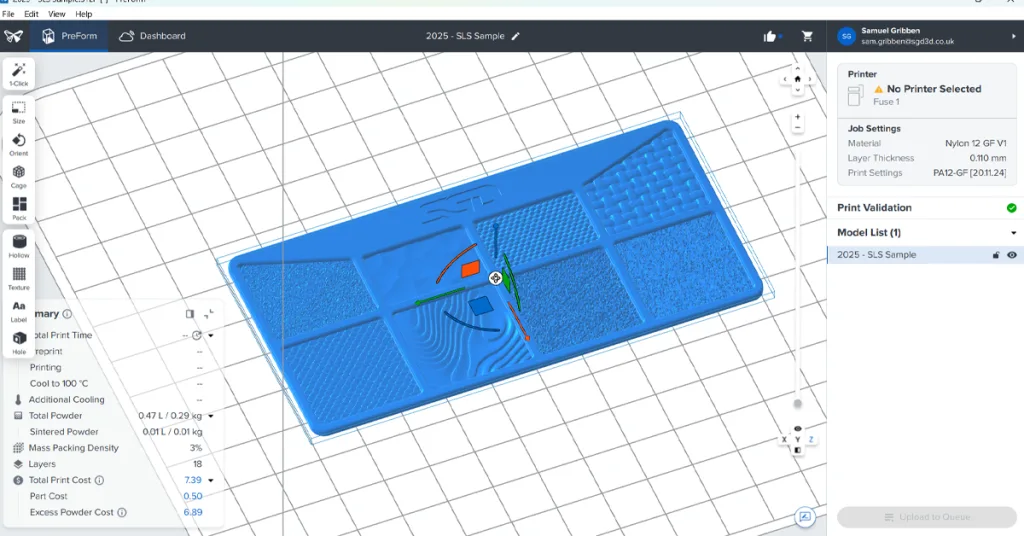

How To Guide: Applying Textures in Formlabs PreForm Software

One of the most striking yet underutilised features in Formlabs PreForm is its native support for texture mapping — letting you add rich surface detail without needing to sculpt every bump in CAD. In this how-to guide, we’ll walk you through how to paint faces in your 3D model, export the appearance data via STEP, and then bring it into PreForm for final texture assignment.

Whether you’re after a subtle grain, a bold embossing, or a complex displacement pattern, this workflow lets you blend the freedom of CAD design with PreForm’s intuitive texture tools. We’ll also highlight key tips — like choosing the right amplitude for SLS parts and printing textured surfaces at angles — to help you get the most from each print.

Ready to bring your parts to life? Let’s dive in.

How Aerospace 3D Printing in Derby is Transforming Manufacturing and Innovation

Aerospace 3D printing in Derby is reshaping how components are designed, tested, and produced. From lightweight engine parts to rapid prototyping, local manufacturers are using additive technology to cut lead times, reduce costs, and drive innovation across the Midlands’ thriving aerospace sector.

How Nottingham’s Education and Research Sector is Using 3D Printing for Innovation

Nottingham’s universities, schools, and research centres are embracing 3D printing to transform the way students and academics learn, teach, and innovate. In classrooms, additive manufacturing brings STEM to life

Design Guidelines for SLS 3D Printing

Designing for Selective Laser Sintering (SLS) requires careful attention to wall thickness, tolerances, shrinkage, and part orientation. Unlike SLA or FDM, SLS allows complex geometries without support structures, but following design guidelines is essential for accuracy and repeatability. In this guide, we cover key rules for successful SLS design, from minimum feature sizes to assembly fits, as well as how industries like aerospace, automotive, and medical rely on precision in SLS printing.

August Bank Holiday 2025

SGD 3D will be closed for the August Bank Holiday on Monday 25th August 2025. Any orders or enquiries placed during this time will be handled as soon as we reopen on Tuesday 26th August.